Researchers have found a new alloy that can act as an effective magnetic refrigerant that can be an alternative cooling agent for minimising greenhouse gas emissions and meet the global demand for higher energy efficiency for tackling global warming.

Magnetic refrigeration offers an energy-efficient and environment-friendly cooling technology as an alternative to the vapor-cycle refrigeration technology in use today. Hence efforts are on to fabricate magnetic refrigerators for household, industrial, and technological applications.

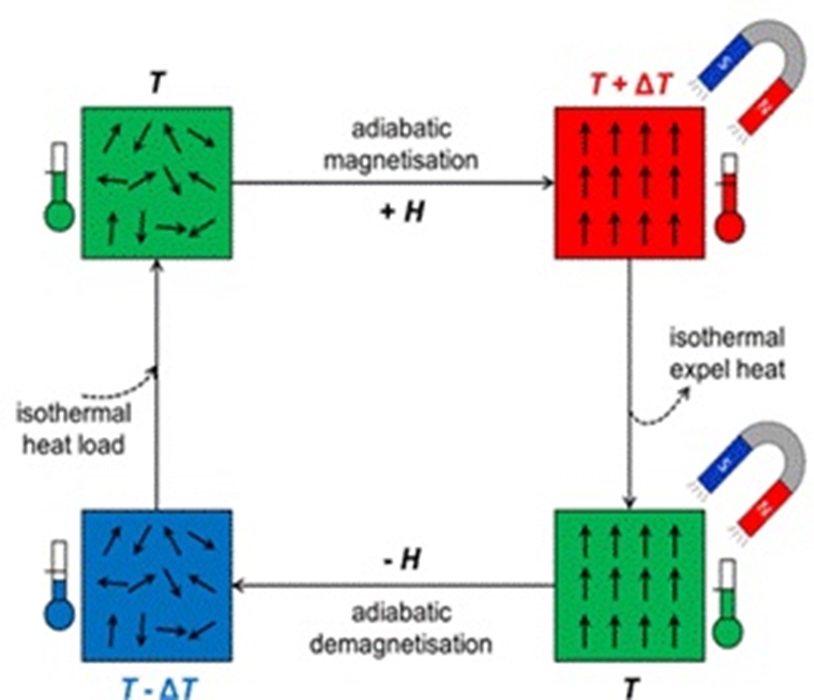

Magnetic cooling effect (MCE) is defined as the reversible temperature change of a magnetic material when it is subjected to an external applied magnetic field. In the magnetic refrigeration cycle, a magnetic field is applied on the magnetic material under an adiabatic process (no exchange of heat with the surrounding). Initially randomly oriented magnetic moments get aligned along the external magnetic field, resulting in the heating of the magnetic material. This heat is transferred from the material to the ambience. When the magnetic field is removed during adiabatic demagnetization, the magnetic moments of the material become randomized, resulting in a decrease in temperature below the ambient temperature. This process causes the material to absorb heat from the surrounding heat-transfer medium.

Current research is focused on developing new magnetic materials such as refrigerants. Three critical criteria need to be fulfilled. First, the material must be capable of operating for millions of cycles without any fatigue and failure, the material must have high thermal conductivity and the material should respond to external magnetic field of about 2 T (Tesla) which can be generated by permanent magnets.

Since most of the materials developed so far show giant magneto caloric effect (GMCE) only at fields as high as 5 T, there is an urgent need to look for materials in which GMCE is achieved in lower fields.

A team SN Bose National Centre for Basic Sciences, an autonomous institute of the department of science and Technology (DST) experimented with a certain type of alloys called all-transition metal based Heusler alloys (magnetic intermetallics with face-centered cubic crystal structure) in their search for material exhibiting giant reversible MCE.

The team at SN Bose Centre has chosen Ni (Co)-Mn-Ti Heusler system because such systems often exhibit multifunctional properties with ultrahigh mechanical stability because of their intrinsic d-d hybridization.

In their study published in the journal Physical Review Materials they have found giant reversible MCE and magneto resistance (MR) in bulk Ni35Co15Mn34.5−xCuxTi15.5 (x = 1, 2, and 3) under an applied magnetic field of 5 T and 7 T. Scientists have shown that Cu doping in the Mn site pulls the magnetic transition towards structural transitions and therefore the distance between them decreases. This is because Cu strengthens the metallic character of the Ni–Ti bond and at the same time weakens the magnetic Mn–Mn exchange interaction.

Polycrystalline samples of Ni35Co15Mn34.5−xCuxTi15.5 (x = 1, 2, and 3) were prepared by arc melting technique. To ensure compositional homogenization, the samples were re-melted five to six times on each side. The melted ingots were wrapped with tantalum foil and sealed in an evacuated quartz tube. The samples were annealed at 1323 K for four days and quenched in ice water. The actual compositions of the samples were verified by energy dispersive x-ray.

Authors claimed from the temperature and field-dependent magnetization measurements that this investigated alloy yields giant reversible MCE parameters.

Change of fundamental ordering of spins and consequently the crystal and magnetic structure resulted in a significant change in the electrical resistance.

The researchers claim that the obtained magnitude of reversible MCE and MR is the highest reported value so far in the all-d-metal Heusler family. The concurrent observation of refrigerant capacity and MR is also very rare in Heusler alloys. The search for the right kind of magnetic material has yielded positive results at the S.N. Bose Centre Lab. The synergistic combinations of giant MCE and MR by proper tailoring of Cu-doped Heusler alloys may lead to a diverse range of solid state-based technological applications.

Tags: Cooling Technology, Global warming, Greenhouse Gas Emissions, MCE

Recent Posts

Hyundai Glovis to Retrofit Seven PCTCs with Avikus AI Navigation System

Super Terminais orders three more Konecranes Gottwald ESP.10 Mobile Harbor cranes

Covestro and HGK Shipping Extend Partnership to 2040 with Focus on Wind-Assisted Vessel Retrofit

Artemis Technologies Successfully Demonstrates 100 Percent Electric Crew Transfer Vessel at Aberdeen Offshore Wind Farm

IACS Council Advances Decarbonisation, Digitalisation and Governance Priorities at C91 Meeting in Beijing

Japan Launches Major R&D Project to Advance Shipbuilding with Alternative Fuels

EU Adopts Emissions Standards for Low Carbon Hydrogen to Bolster Clean Energy Market

Trafigura to Implement ZeroNorth’s AI Platform Across Global Fleet