A new sustainable and practical method for producing hydrogen from water has been discovered by a team of researchers at the RIKEN Center for Sustainable Resource Science (CSRS) in Japan led by Ryuhei Nakamura. Unlike current methods, the new method does not require rare metals that are expensive or in short supply. Instead, hydrogen for fuel cells and agricultural fertilizers can now be produced using cobalt and manganese, two fairly common metals. The study was published in Nature Catalysis.

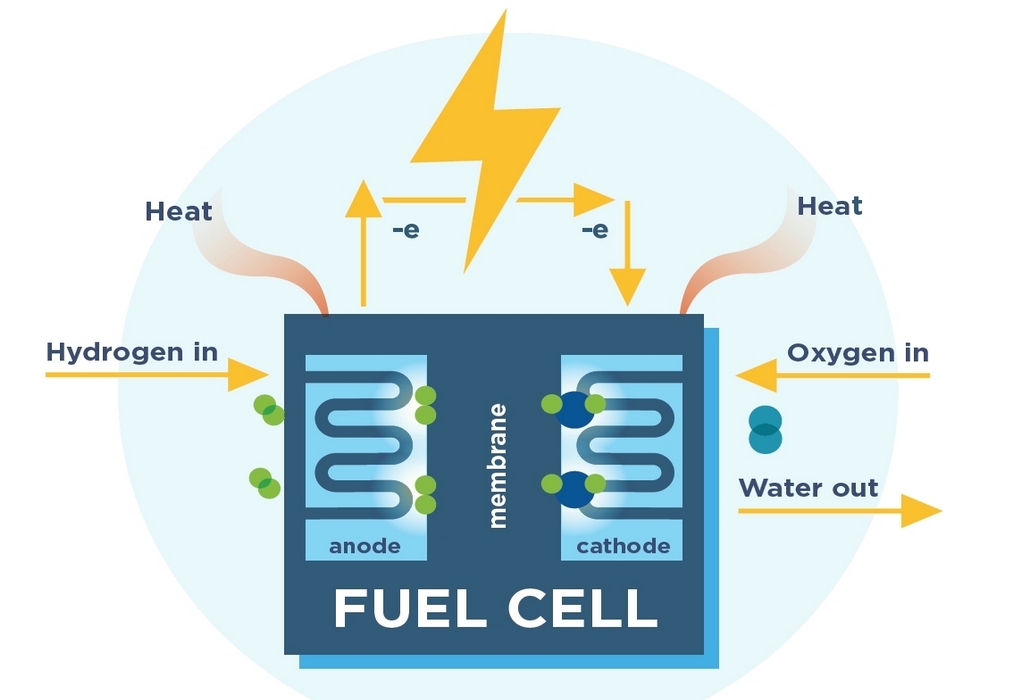

Unlike conventional fossil fuels that generate carbon dioxide upon combustion, hydrogen is a clean fuel that only produces water as a byproduct. If hydrogen can be extracted from water using renewable electricity, the energy grid can be made clean, renewable, and sustainable. Additionally, hydrogen is the key ingredient needed to produce ammonia, which is used in virtually all synthetic fertilizers. But instead of cleanly extracting hydrogen from water, currently, ammonia plants use fossil fuels to produce the hydrogen they need.

So why are we still using fossil fuels? One reason is that the hydrogen extraction process itself—electrolysis—is expensive and not yet sustainable.

“This is primarily due to a lack of good catalysts,” says Nakamura. “In addition to being able to withstand the harsh acidic environment, the catalyst must be very active. If not, the amount of electricity needed for the reaction to produce a given amount of hydrogen soars, and with it, so does the cost.”

Currently, the most active catalysts for water electrolysis are rare metals like platinum and iridium, which creates a dilemma because they are expensive and considered “endangered species” among metals. Switching the whole planet to hydrogen fuel right now would require about 800 years’ worth of iridium production, an amount which might not even exist. On the other hand, abundant metals such as iron and nickel are not active enough and tend to dissolve immediately in the harsh acidic electrolysis environment.

The mixed cobalt manganese oxide, Co2MnO4. (Right) a frame from a video showing hydrogen being produced through electrolysis at the current density of 1000 milliamperes per square centimeter. Credit: RIKEN

In their search for a better catalyst, the researchers looked at mixed cobalt and manganese oxides. Cobalt oxides can be active for the required reaction, but corrode very quickly in the acidic environment. Manganese oxides are more stable, but are not nearly active enough. By combining them, the researchers hoped to take advantage of their complimentary properties. They also had to consider the high current density needed for practical application outside the laboratory. “For industrial scale hydrogen production, we needed to set our study’s target current density to about 10 to 100 times higher than what has been used in past experiments,” says co-first author Shuang Kong. “The high currents led to a number of problems such as physical decomposition of the catalyst.”

Source: https://phys.org/news/

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham