Brunvoll’s strategy for production in Norway was established as early as the 1990s, with the forward-thinking Brunvoll family at the forefront. This has led to continuous and significant investments in enhancing the factories’ competitiveness and raising internal expertise to meet our customers’ high demands and expectations.

“We are convinced that having a fully integrated value chain where we have complete control from A to Z is the right thing for Brunvoll and our further development. Despite a business policy from the government that continually challenges local Norwegian ownership and production, we at Brunvoll are incredibly proud that as a family-owned group, we once again take a leap and invest significantly to enhance our competitiveness.”, says Group CEO Kåre Øyvind Vassdal.

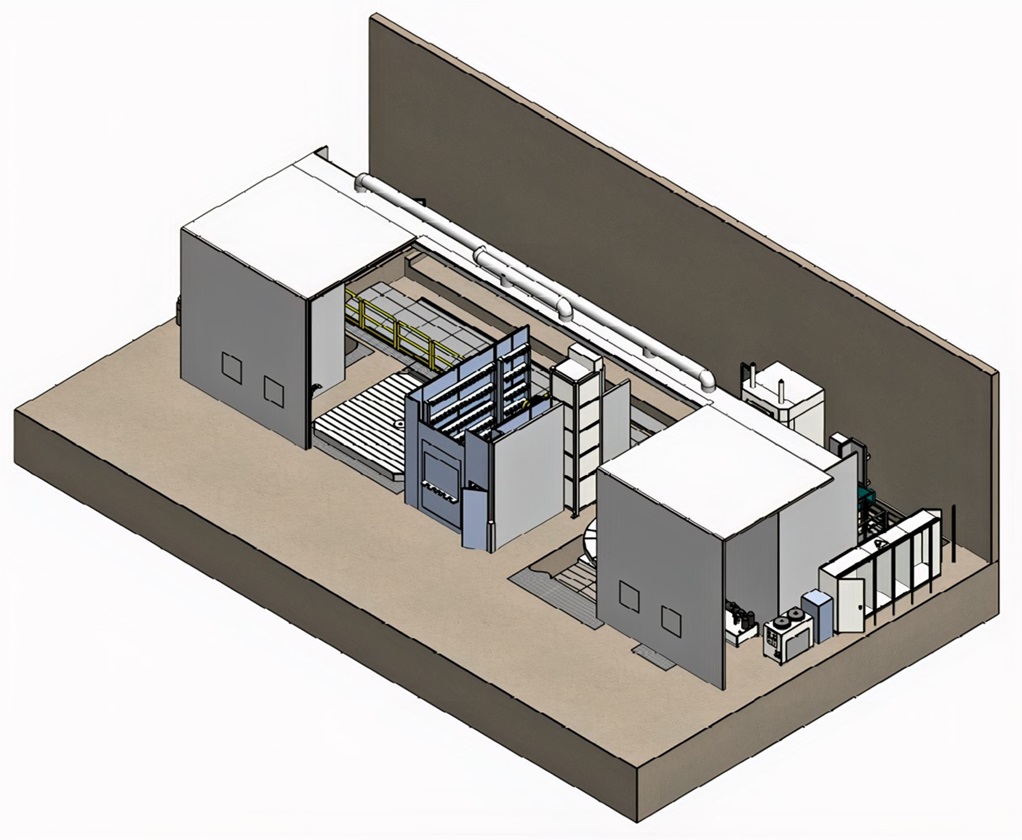

The Brunvoll group is currently experiencing significant growth, and in connection with this, we have placed orders for two large new and high-tech machines to further expand our capability and apacity.

One large machining center for gearbox housings are ordered for the factory in Volda. The other machine on order is a large combination turning and machining center for the factory in Molde. The machines will be delivered by the supplier PAMA S.P.A in Q1 2025. PAMA is an Italian company with a 90-year long history of delivering medium to large machines with high requirements to rigidity and shares the same passion as Brunvoll for precision.

Source: Brunvoll.

Tags: Brunvoll, Italian, Machines

Recent Posts

Polish Delegation and JKSH Group Explore Green Energy Project in Andhra Pradesh

bigbasket Expands EV Delivery Fleet to 50 Cities with Support from Kazam

Axpo Completes Spain’s First Ship-to-Ship Bio-LNG Bunkering for Container Vessel at Algeciras

BLG LOGISTICS and Liebherr Strengthen Sustainable Port Operations with Shore Power-Ready Crane in Bremerhaven

Beijing Maersk Enters Service as Latest Methanol-Powered Containership

Yinson GreenTech and C-Torq Deliver Marine Battery System for Hybrid Vessel in the Middle East

Singapore Tugboat Receives Biofuel-Ready Notation Following Retrofit

NYK Names Sixth Dual-Fuel LPG Carrier “Luna Pathfinder”