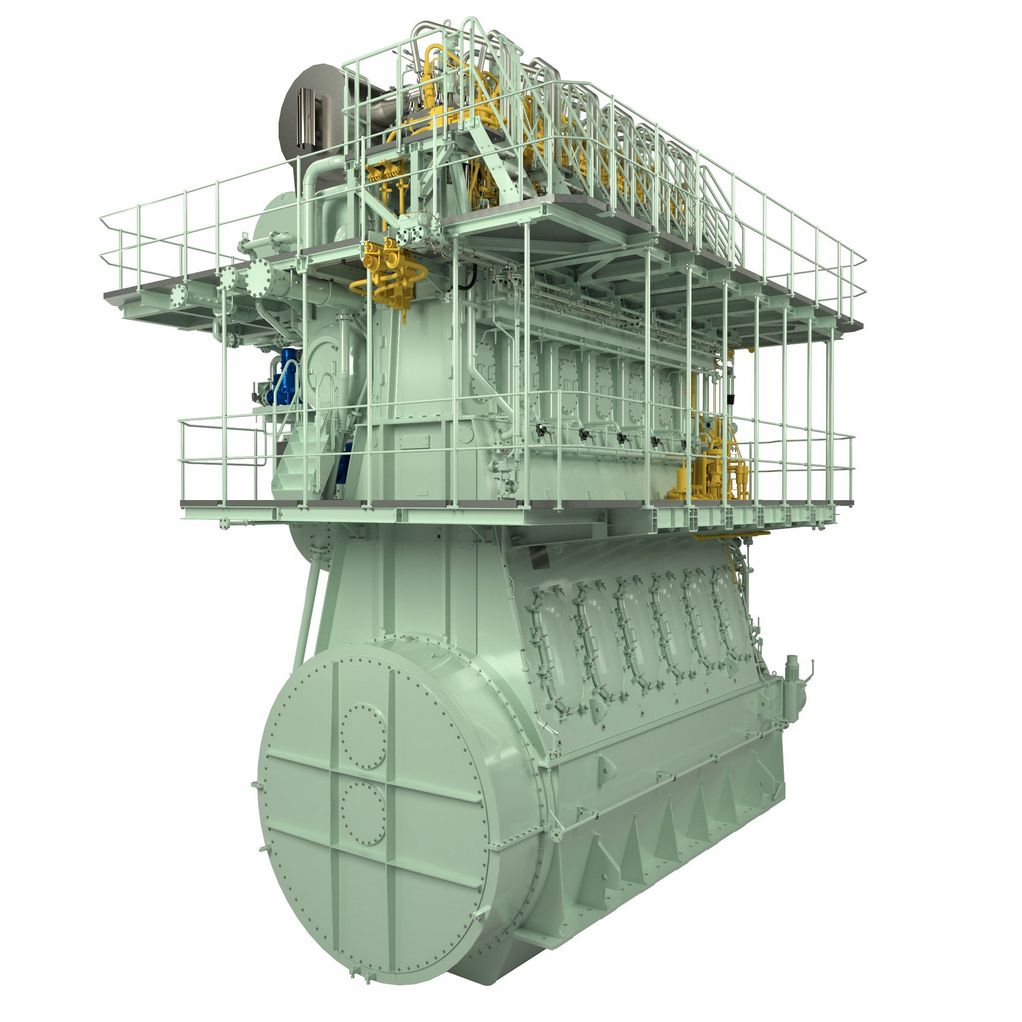

Japan’s Hitachi Zosen is working with MAN Energy Solutions to offer clients methanol engine conversions plans amid rising inquiries for green retrofit solutions.

Test operations will begin in 2024 at a Hitachi Zosen plant in Kumamoto prefecture, on Japan’s southernmost main island of Kyushu.

MAN estimates that 2,800 vessels with MAN two- and four stroke engines are eligible for conversion today and could save more than 97m tons of carbon dioxide (CO2) emissions annually when run on green fuels.

Contacted by Splash earlier this year, Dr Tristan Smith, associate professor in energy and shipping at UCL Energy Institute, argued the potential for engine retrofits among today’s global merchant fleet was “thousands of ships per year”.

Smith and his team have a paper at the International Maritime Organization on the matter discussing the costs involved compared to using more expensive drop-in fuels or scrapping.

The cost of retrofitting, including the fuel storage and fuel supply system, ranges between $5m and $15m depending on the type of fuel and, as a rule of thumb, this should not exceed 25% of the newbuild cost of a ship to be economically viable, according to advice from DNV.

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham