After close to 20 years of scientific research into fuel cell and electrolyser membranes, Horizon Fuel Cell Technologies is announcing a scientific breakthrough in Anion Exchange Membrane technology.

Green hydrogen costs need to drop significantly for the global community to meet its decarbonization targets while at the same time competing effectively with fossil fuel alternatives. AEM (Anion Exchange Membrane) electrolysis stands out as a highly promising technology due to strong dynamic response capabilities, much lower equipment costs, and higher efficiencies. However, this emerging technology is still considered by many analysts and experts as relatively unproven.

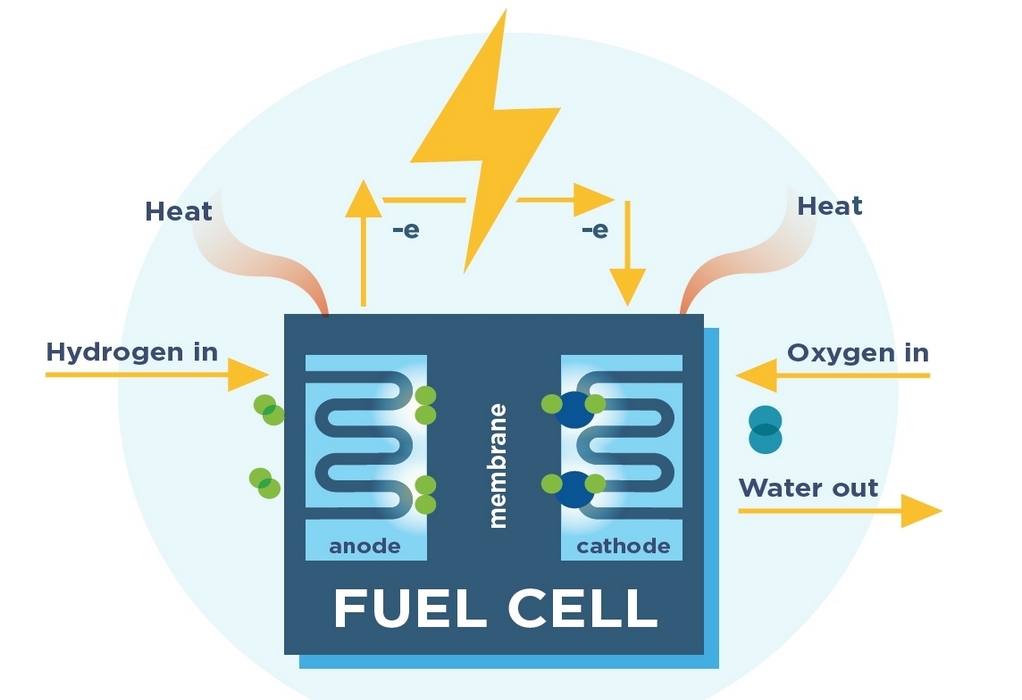

The membrane is one of the critical components influencing performance, longevity, efficiency, and cost of AEM electrolysis systems: considered the keys to unlocking the potential for large-scale commercial deployment of AEM-based hydrogen production equipment. In February 2024, Horizon announced a significant breakthrough in their AEM development, and now the company is releasing important specifications and test data.

Horizon’s membrane material, structure and production method yield dramatically improved ion conductivity while achieving robust mechanical and chemical stability over extended periods. A fully saturated carbon-hydrogen polymer resin is used as the base material for the functional groups, with a thickness of 50μm, only 1/10 the thickness of typical polyphenylene sulfide (PPS) membranes used in alkaline electrolysers.

With a tensile strength exceeding 65MPa, the Horizon membrane demonstrates a robustness 1.5 to 2 times greater than competing products that have been evaluated. As a result, less material is needed and lower internal resistance can be achieved, and electrolysers utilising such membranes will be able to produce green hydrogen at the lowest possible cost.

Horizon anion exchange membrane research and development was in line with the company’s U.S. Patent Application No. 2007/0275291 featuring multilayer mechanical and chemical reinforcement. The company continued its membrane development in the past decade to improve both operating performance and production process.

The latest scientific breakthrough facilitates the mass production of a new breed of robust AEM electrolysers, enabling higher pressure tolerance and superior gas barrier properties between the hydrogen and oxygen sides, thereby ensuring enhanced safety during operation. Testing outcomes reveal that under equivalent conditions, both the performance and longevity of Horizon’s AEM significantly surpass competing products from global suppliers.

Historically, 99% of the world’s industrial hydrogen has been produced using steam reforming of natural gas, a process that releases 10 tons of CO2 for every ton of hydrogen produced. With Horizon’s scientific breakthrough in long-life AEM materials, green hydrogen can cost-effectively displace the grey hydrogen valued at more than $200 Billion per year, used in the production steel, fertilisers, chemicals and oil refining. This also paves the way to competitive operational costs of hydrogen-electric power in mobility and stationary applications.

Tags: AEM Technology, Fuel Cell, US Patent

Recent Posts

Scandlines Nears Delivery of Zero Emissions Ferry Following Successful Sea Trials

India faces emission roadblocks with rising net-zero demands

Green Energy Resources invests in two electric Liebherr LHM 550

NYK Launches Continuous Use of Bio LNG Fuel on Car Carriers to Advance Decarbonization Goals

Yang Ming Expands Fleet with Methanol and LNG Dual-Fuel Vessels Under Fleet Optimization Plan

ClassNK Advocates Speed Gap Monitoring to Optimize Fuel Efficiency in Heavy Weather

Wärtsilä’s retrofit package for the Corsica Linea ferry Pascal Paoli has resulted in fuel savings of up to 22 percent Corsica Linea

COSCO Shipping Names Second Methanol Dual-Fuel Containership in Yangzhou