The spread of eco-friendly hydrogen technology is expanding across various industries in South Korea, including steel, power generation, shipbuilding and aviation, as the use of hydrogen offers long-term benefits both environmentally and economically.

The use of hydrogen in Korea is expected to increase to produce eco-friendly steel. The challenge now is to develop technologies that utilize 100 percent hydrogen, which will fundamentally eliminate carbon emissions in steel production.

Typically, steel production involves putting iron ore and coal into a furnace to make iron. Carbon monoxide is used as a reducing agent, which results in the production of pure iron while emitting carbon dioxide as a byproduct.

To address this issue, POSCO has been using a process called the Finex process, which involves putting iron ore into a fluidized bed reactor instead of a furnace. This process uses carbon monoxide and hydrogen as reducing agents, but currently, the hydrogen content is only at 25 percent. To fundamentally eliminate carbon emissions, a technology that utilizes 100 percent hydrogen is needed. POSCO is partnering with Hyundai Steel Co. to challenge the extraction of molten iron using 100 percent hydrogen.

Since only hydrogen is used as a reducing agent, the byproduct is water vapor, making it more eco-friendly.

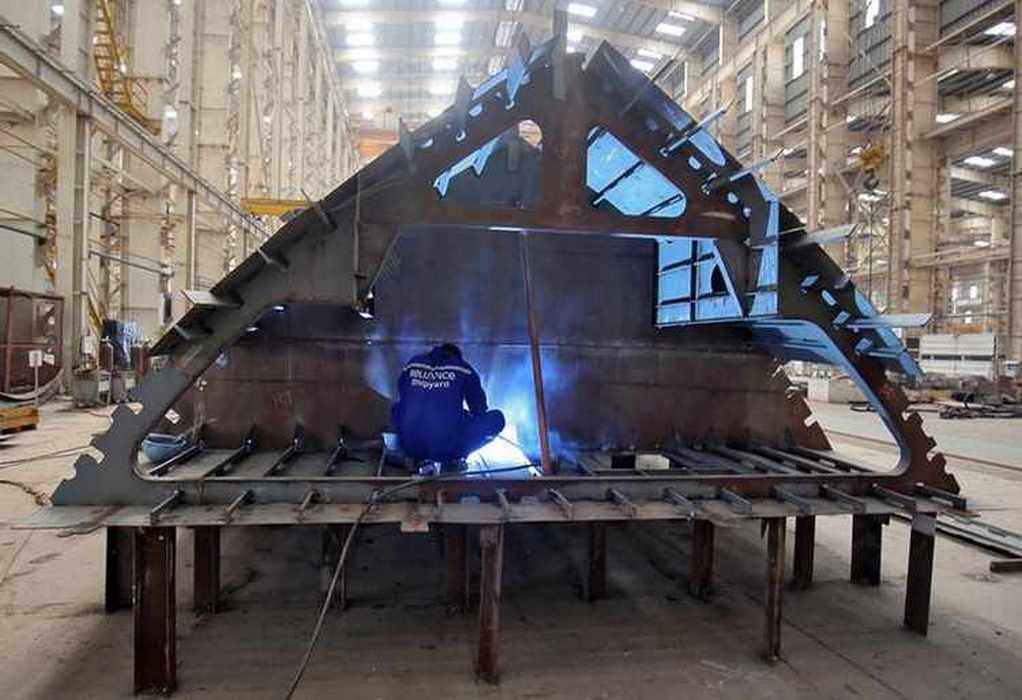

The use of hydrogen is also expected to bring long-term benefits to the shipbuilding industry. HD Hyundai Co. recently developed the first LNG-hydrogen dual fuel engine in Korea, which significantly reduces emissions of harmful exhaust gases such as sulfur oxides, nitrogen oxides, carbon dioxide, and particulate matter by selectively using diesel fuel and LNG-hydrogen mixed fuel.

The application of hydrogen-fueled engines to liquefied hydrogen carriers is expected to maximize the operational efficiency of ships. This is because the hydrogen evaporative gas generated during transport can be reused as fuel, minimizing the amount of hydrogen lost during voyages.

Samsung Heavy Industries Co. recently succeeded in developing a liquefied hydrogen fuel cell propulsion system for ships.

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham