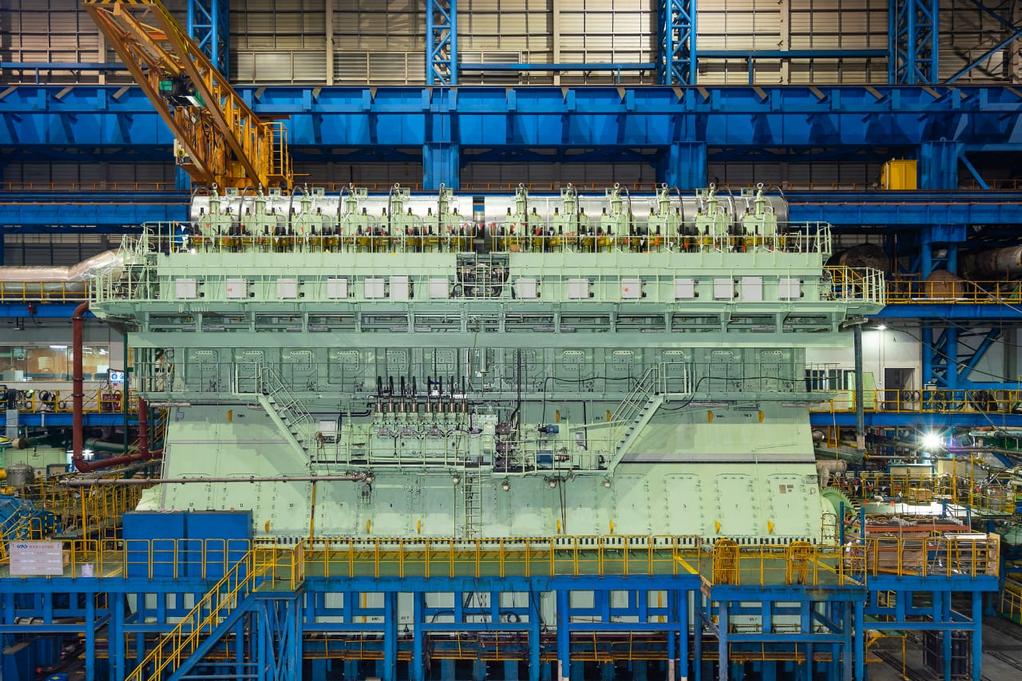

Swiss marine power company WinGD will record the first installation of its new X-S short-stroke engine design following successful factory acceptance tests with engine builder Dalian Marine Diesel in March. The six-cylinder, 62cm-bore 6X62-S2.0 engine will be installed on a pulp carrier being built for a Chinese owner at COSCO Dalian shipyard.

The X-S series succeeds the well-established RT-flex50 and RT-flex58 engines and is available in 52cm and 62cm bore sizes, for the range of fuel options including traditional diesel or dual-fuel LNG, methanol and ammonia operation. The combination of a compact, simple, design and best-in-class fuel efficiency – around 10g/kWh lower than equivalent RT-flex engines, a saving of around 4% depending on operating profile – make the new platform ideal for vessels that benefit from short-stroke engines.

WinGD Director Sales, Volkmar Galke said: “The factory test for our first X-S engine confirms that this new generation of short-stroke engines delivers outstanding value for ship operators, providing significant operating cost advantages while enabling high efficiency in compact ship designs. We anticipate strong uptake as the global fleet of merchant vessels using short-stroke engines is renewed and prepares for future regulation demands.”

The X-S combination of shorter stroke length and higher engine speeds allows smaller propellers to generate similar power to long-stroke engines of similar cylinder bore. The compact design is well-suited to vessels that operate in shallow drafts or need lower main deck or engine room height. The existing fleet of short-stroke engine users includes container feeders, car carriers, multipurpose cargo vessels, ro-ro/con-ro vessels and several others. The X-S series has also been designed specifically to make short-stroke engines an attractive power solution for bulk carriers and tanker vessels that do not require the biggest engine bore sizes.

As well as reducing fuel consumption, the operating costs of the new X-S engines offer further efficiencies as a result of its robust and lightweight design. Maintenance is simplified due to lower piston height, while the engines also feature extended time between overhauls compared to previous short-stroke generations.

For dual-fuel X-S engines, intelligent control by exhaust recycling (iCER) allows vessels to reduce fuel consumption and meet Tier III NOx in both gas and diesel modes without separate selective catalytic reduction (SCR), while reducing methane slip when using LNG.

The first installation of an iCER-equipped X-S engine is currently under preparation for a 7,000 CEU pure car/truck carrier (PCTC). Those X62DF-S engines will also feature WinGD’s Variable Compression Ratio (VCR) technology, allowing further efficiency improvements by dynamically optimising engine compression ratio for the fuel used, engine load, ambient conditions and other parameters.

Tags: Design, Engine, WinGD

Recent Posts

Robert Allan Ltd. to Design Fully Electric AmpRA 3600 Tug for Tianjin Port

U-Ming Marine Conducts First Bunkering of FAME B24 Biofuel

DNV Validates Electric Hydrogen’s HYPRPlant for Safety, Efficiency and Commercial Readiness

Nepal Eyes Green Hydrogen Future with Policy Push and Hydropower Potential

India Tests First Hydrogen-Powered Rail Coach at ICF Chennai

Scandlines Nears Delivery of Zero Emissions Ferry Following Successful Sea Trials

India faces emission roadblocks with rising net-zero demands

Green Energy Resources invests in two electric Liebherr LHM 550