Developer and manufacturer of high-performance natural and synthetic graphite sheets, NeoGraf Solutions, has been awarded a $2mn grant by the US Department of Energy (DOE) for the development of graphite bipolar plates for heavy-duty fuel cell applications.

NeoGraf says it will use the grant to develop flexible, low-cost bipolar plates for heavy-duty fuel cell applications within the US trucking and mass transportation sectors.

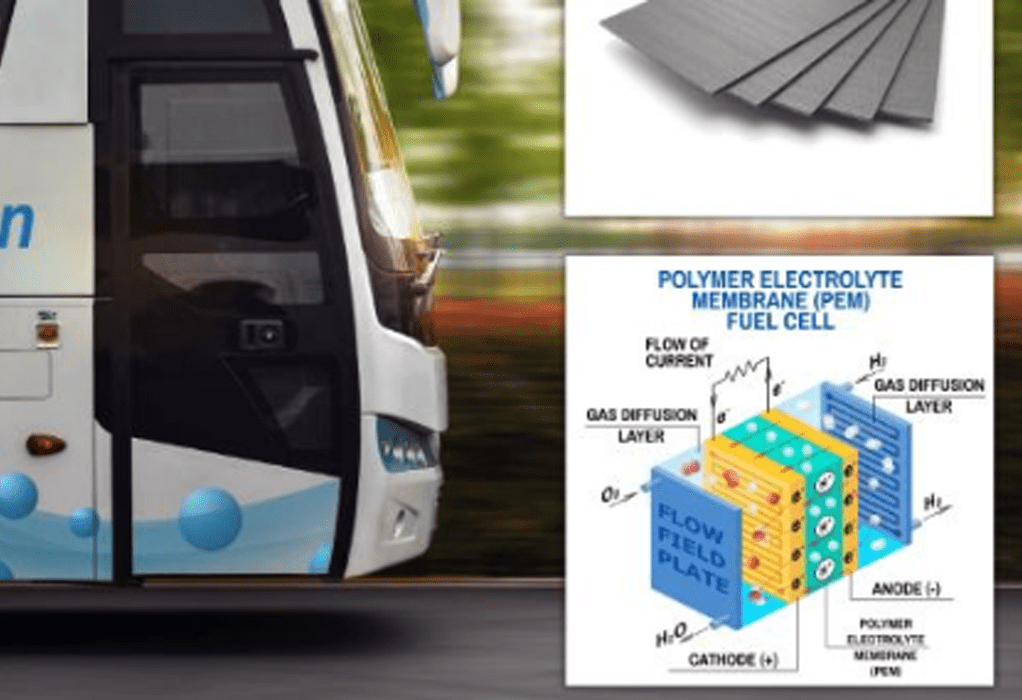

Bipolar plates are a key part of the electrical circuitry of a fuel cell stack. Currently, they are primarily used in buses in China and for material handling applications in North America, but the DOE aims to expand fuel cell use in the trucking and transportation industries.

“This important award validates NeoGraf’s technology and its potential use in next-generation fuel cell materials,” commented Andy Reynolds, CEO of NeoGraf Solutions. “Fuel cell technology is growing at an exponential pace as global environmental demands increase, requiring companies to keep pace with cutting-edge technology that enhances productivity and eliminates waste.”

To support the development of fuel cells for heavy-duty applications, such as those within the commercial sector, the DOE has been investing in technologies that expand hydrogen infrastructure and create fuel cell systems that are cost-competitive at high volumes.

NeoGraf’s proposal focuses on the development of flexible graphite that supports cost targets and high-volume manufacturing requirements. One of the project’s main goals is to reduce the cost of bipolar plate graphite for next-generation heavy-duty fuel cell applications by developing thin, durable, flexible graphite. The technology will enable progress toward meeting 2030 system-level heavy-duty truck targets of US$80/kW system costs and a 25,000-hour durability target.

“The success of this project depends on our ability to produce low basis weight, thin, flexible graphite with very low content of leak-inducing impurities,” added Reynolds.

The three-year project is scheduled to begin at the end of the year, with Ballard Power Systems to participate by converting the NeoGraf graphite material into bipolar plates. NeoGraf will then demonstrate that the fuel cell stack’s performance meets heavy-duty application requirements.

Source: https://www.enginetechnologyinternational.com/

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham