Using conductive metal oxides as catalysts, researchers have developed an electrification strategy aimed at decreasing the ignition temperature of soot. Relevant results were published in Nature Catalysis.

This research was conducted by Prof. Zhang Jian’s group at the Ningbo Institute of Materials Technology and Engineering (NIMTE) of the Chinese Academy of Sciences (CAS) and Prof. Zhang Zhaoliang’s group of Jinan University.

Catalytic soot combustion is the most efficient after-treatment technology for reducing diesel soot particulate emissions, which can trigger severe health and environmental problems. However, urban diesel vehicles idle frequently in traffic with exhaust temperatures reaching only 100–200 degrees Celsius, which is too low for catalytic soot combustion to occur.

Aiming at realizing soot ignition at low temperatures, researches at NIMTE and Jinan University designed an electrification strategy for soot combustion. Typical conductive metal oxides with excellent oxidation resistance and conductivity were employed as catalysts.

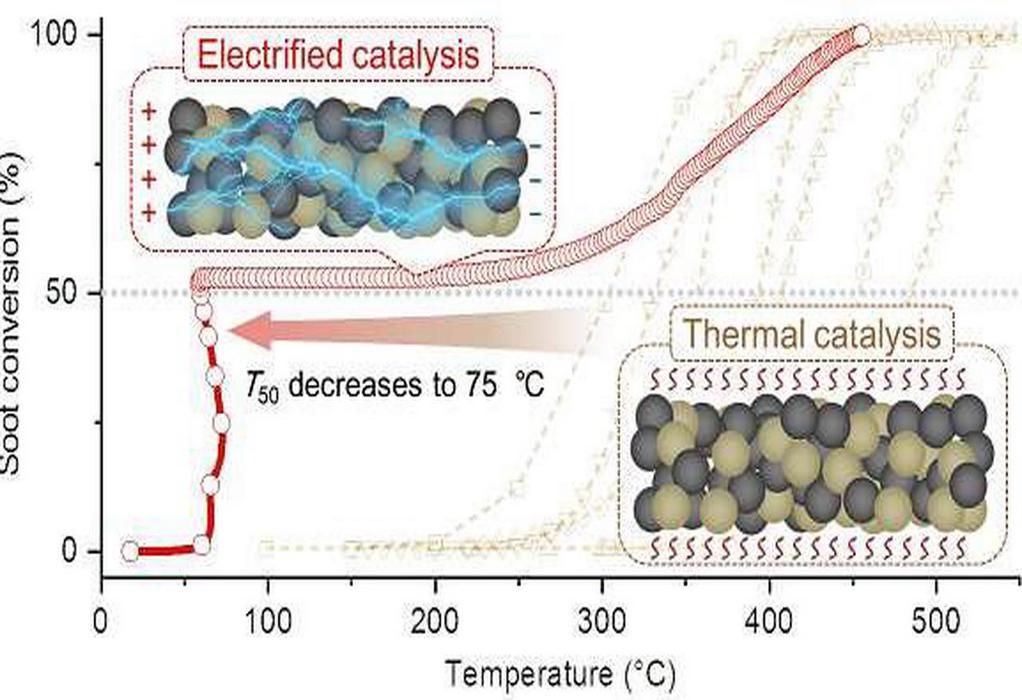

According to the researchers, 53 percent of the soot in the mixtures was combusted within only a few minutes at <75 degrees Celsius. The performance achieved was far superior to that with conventional thermal catalytic soot combustion, generally with T50 (the temperature at which 50% of soot is converted) >300 degrees Celsius. Thus, the dependence of electrification on contact conditions is much weaker than that of the conventional thermal process.

In regard to energy demand, the electrification process consumes considerably less energy than the thermal process, with an energy-saving rate of one to two orders of magnitude.

In addition, two key mechanisms for the performance were illuminated, electrically driven release of lattice oxygen from catalysts accounts for the rapid soot ignition at low temperatures, while the opposite electrostatic fluidization between the conductive catalyst and soot particles is responsible for the catalyst–soot contact efficiency improvement.

The electrification process has achieved a breakthrough in the ignition temperature for soot combustion, presenting a prospective strategy to solve the common issue of all automotive after-treatment at low exhaust temperatures.

Promisingly, the strategy could be integrated into vehicle design, especially that of hybrid electric vehicles, by virtue of onboard electric power systems.

Source: https://phys.org/news/

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham