In 2020, engineer Vishal Prasad Gupta received approval from the Union Ministry of Petroleum and Natural Gas to set up ‘More Mileage’, his own petrol pump, in Ranchi, Jharkhand.

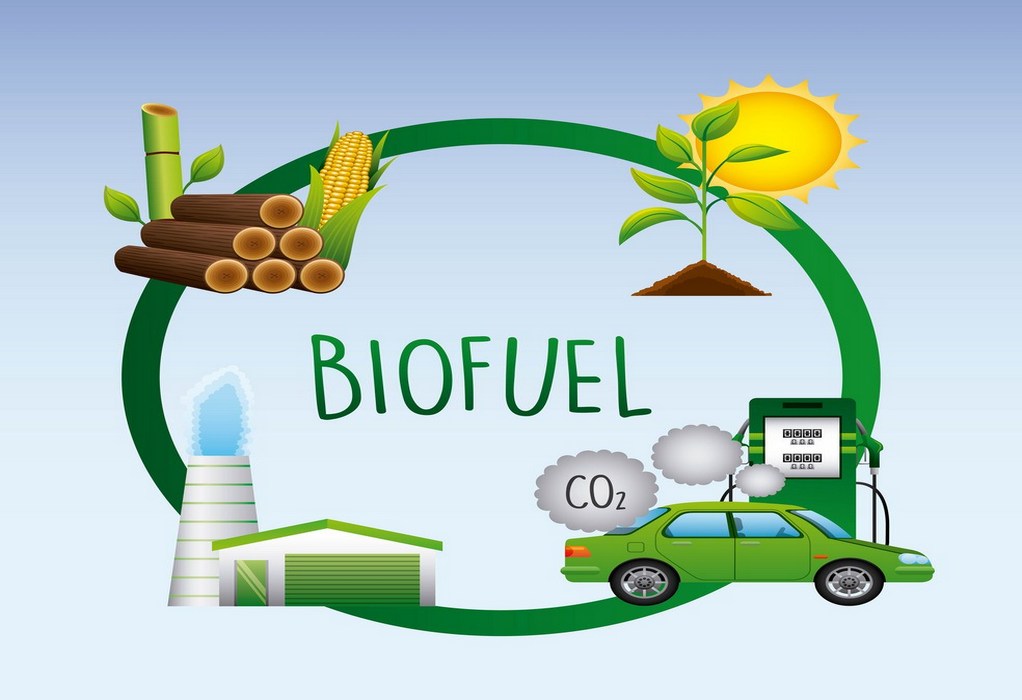

The 42-year-old has been credited with innovating a biofuel manufactured from a species of microalgae native to Jharkhand’s ponds, which he says is not only more environmentally friendly than petrol and diesel, but also easy on the pocket.

The biofuel, which can be used in all vehicles with EM590 diesel engines, costs Rs 78 per litre, a cheaper alternative to diesel, which is currently priced at Rs 92 in Ranchi. Meanwhile, bioethanol costs Rs 72, which Vishal says can replace petrol currently priced at Rs 99 per litre.

“I come from a petroleum family and always wanted to develop a carbon-neutral and cost-efficient fuel for the common man. My grandfather worked for Burma-Shell in 1932 (now Bharat Petroleum), and my father started working for Indian Oil Corporation (IOC) as a dealer in 1969 as well,” Vishal told.

Vishal is in talks with civic officials to pursue a Memorandum of Understanding (MoU) with the Ranchi Municipal Corporation, following which he would be able to make use of city dams for the cultivation of algae and manufacture biofuel on a larger scale.

Research and development

Cultivation of microalgae in a pond at More Mileage’s manufacturing plant, Ranchi. (Source: Vishal Prasad Gupta)

After graduating from the Birla Institute of Technology, Mesra, Vishal worked as a marketing specialist with TotalEnergies SE (then Total France), a multinational oil and gas company that had an active MoU with IOC. He also worked with several other PSU (Public Sector Undertaking) units for 15 years before undertaking research work on third-generation fuels in 2018, when the Union Cabinet had also approved the Current National Policy on Biofuels.

Vishal partnered with Dr Kumar Bhupati, a professor at Birsa Krishi Vishwavidyalaya in Ranchi, who was researching microalgae as feed for livestock owing to its rich content of proteins, amino acids, minerals, and other nutrients. It was then that Vishal realised the algae had chemical components similar to those in crude oil, and that it could be used to develop biofuel.

It took about two months for him to receive approval for his creation by the Petroleum Conservation Research Association, Government of India. Vishal says that owing to the goodwill he enjoys in his hometown and a strong network in the industry, he was easily able to market his product. He claims to sell as much as 2,000-2,500 kls (kilolitres) of biofuel daily, and has sold around 2,50,000 kls of biofuel till date. He has also made commercial sales to Tata Motors (250 kls) and Damla Bharat Cement (500 kls).

Vishal owns a manufacturing plant alongside Namkum — one he bought from a friend who formerly sold karanja oil and mahua oil — with a daily production capacity of 70,000 kls. With a team of 35 employees, the plant has been operational since December 2020.

How does it work?

Explaining the process, Vishal said that a species of algae called Azolla pinnata, which contains a considerable quantity of oil, is taken out of the pond and put in a chemical compound called hexene. After being treated in the plant, it becomes a lipid in liquid form, following which it achieves the final form of biodiesel or bioethanol.

As much as 7,000 kls of biofuel is produced per batch of production, he says. While a little over 13 hours of sunlight over the plant’s 13 ponds is deemed integral to the process, the plant’s premises also have ultraviolet lamps to aid microalgae cultivation at night. Members of a local NGO help with harvesting the algae and aid the ponds’ upkeep. Vishal has also obtained permission from the civic authorities to make use of public ponds in the city.

“Algae grown on one acre of land can decrease the air quality index (AQI) of the area by 60 per cent. Besides being used as a biofuel source and livestock feed, it helps in creating antioxidants for beauty products and may be used for anti-cancer medicines,” claims Vishal.

Algae is also known for drastically reducing carbon dioxide emissions by converting them into oxygen (and biomass) via photosynthesis. “Removing algae from water bodies also helps clean them and reduce their pH levels, which are about 8-9 with the algae. Water used in the biofuel manufacturing process can also be treated into mineral water,” says Vishal.

Vishal, who lives with his mother and wife, said an algae-based “super fuel”, which would be fit for use in both petrol and diesel-run vehicles, is also in the works. He hopes the country can move past exporting crude oil and achieve self-reliance in terms of acquiring indigenous raw material to produce sustainable fuel.

Source: https://www.thebetterindia.com/

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham