Asenav S.A. shipyard in Chile has placed an order for 2 × 12V175D-MM IMO Tier II engines, each rated at 2,040 kW @ 1,800 rpm. The engines will provide propulsion power for a 70 TBP ASD tug of As Asenav’s own design. The vessel will also be delivered as future-proof, allowing for the retrofitting of exhaust-gas after-treatment to meet IMO Tier III standards.

The engines will be manufactured at MAN Energy Solutions’ dedicated, state-of-the-art Frederikshavn facility in Denmark with delivery scheduled for the end of February 2022, while vessel completion is planned for June 2022.

Benjamin Andres, Head of High Speed Sales, MAN Energy Solutions, said: “This is yet another outstanding reference for the MAN 175D engine with this breakthrough order in the South American tug-building market, which shows such great potential for the future. We believe that the equipment that we are supplying is well suited to the requirements of Asenav and are looking forward to building a close cooperation with them to help deliver an excellent overall product.”

Ricardo Contreras, Engineering New Projects Manager, Asenav S.A. also added: “The selection of this MAN 12V175D-MM was based on the recognised quality of MAN engines in the world market. This specific model fits perfectly to the already proven ASD tugboat developed entirely by As Asenav S.A., where five of these tugs are already for several years working on the Chilean coasts successfully under the strict conditions of the Pacific Ocean. Astilleros Asenav S.A. trusts in the expected results with this new line of MAN engines in Asenav ASD tugs and expects to project this ASD tug concept both in the national and world markets.”

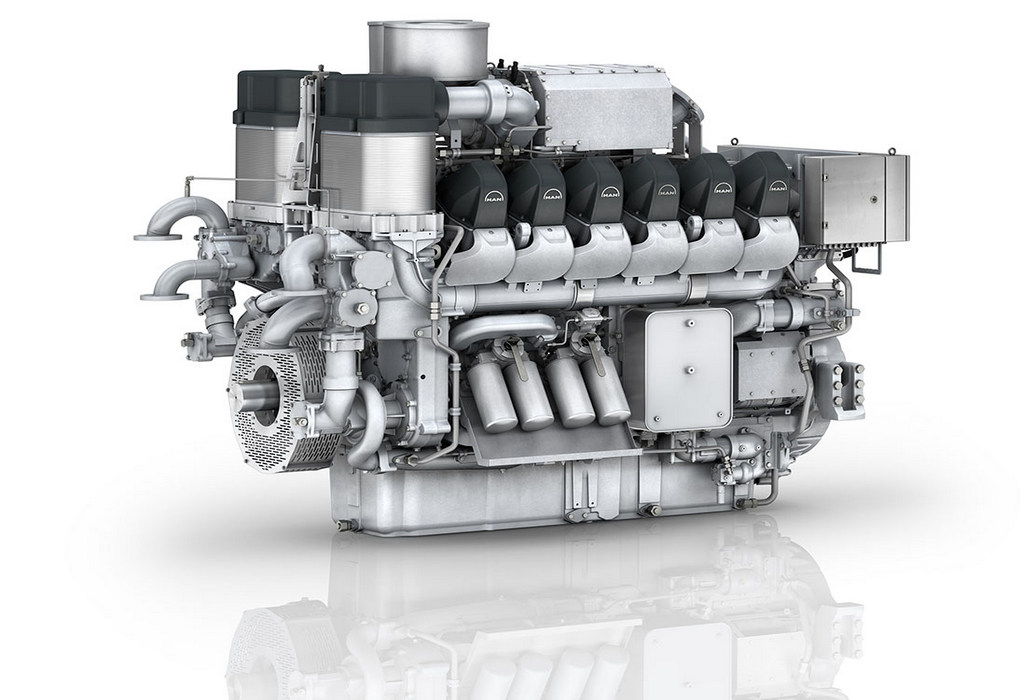

About the MAN 175D engine

MAN Energy Solutions has developed the MAN 175D engine range to supplement and complete its product portfolio in the maritime sector. In three variants of 12, 16 and 20 cylinders, the engine is available with an output ranging from 1,500 to 4,400 Kilowatts and is optimised for propelling ferries, offshore supply vessels, tugs and other working vessels. Other market areas, such as super-yachts and naval marine applications are also served by additional engine variants.

It is also an extremely eco-friendly engine, having been designed from the outset with compliance to latest exhaust-gas-emission standards and considering, as well, future requirements, by utilising a very compact and flexible SCR system, which enables vessel designers to optimise space on board to the maximum.

Source: MAN Energy Solutions

Recent Posts

Power & Propulsion Technology

Alfa Laval and Wallenius to form joint venture AlfaWall Oceanbird for wind-powered vessel propulsion

Power & Propulsion

Mitsui E&S, TGE Marine Open Dialogue with DG Shipping on Engine and Gas Systems Collaboration

Bunkering Methanol

UK’s first commercial biomethanol bunkering service launched at Port of Immingham